The construction industry is evolving rapidly, driven by advancements in technology and the need for sustainability. This blog will explore some of the key trends in construction, including data mining and AI, design-build and design assist, sustainability, worker shortage, safety, and material shortages. These trends are reshaping the industry, improving efficiency, reducing costs, and promoting environmentally friendly practices.

Leverage the power of data

Data mining and artificial intelligence are transforming business operations today. Construction firms that use these tools can improve productivity by as much as 50%. [1] Companies that analyze their data will improve planning and the ability to leverage the strengths of their workforce. They will also anticipate costs and provide reliable information to customers faster. Customers can also reap the benefits of data mining through fewer unexpected expenses and delays. Riley uses these tools to accelerate timelines, meet the demands of tighter schedules, and extend design times when possible. We believe companies can deliver on schedule and on budget and maximize their workforce, despite a climate of worker shortages, by using lean principles and lessons learned from mining data.

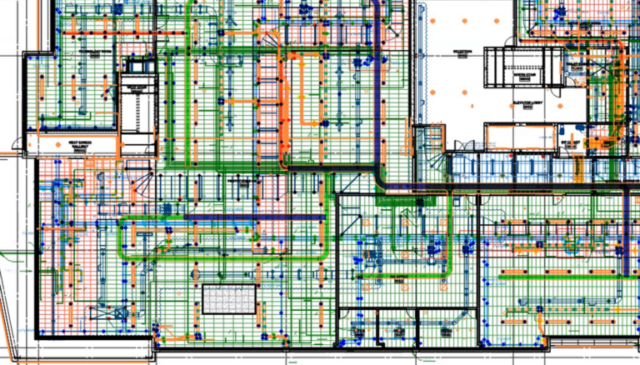

Gain traction with Design-Build and Design Assist

What if you could build faster and more efficiently without adding team members? Design-build and design assist are two approaches that make this possible. The shortening of design phase timelines has sped the adoption of these methods. Not surprisingly, more owners are starting to recognize their cost and efficiency benefits. Involving trade partners early in the design process with these approaches is vital to ensure better coordination and cost estimation. Design for Manufacturing and Assembly (DFMA) is also gaining traction on projects of all sizes and scope, helping teams plan prefabrication and expedite on-site construction times. The use of DFMA principles in construction projects can reduce overall project costs by 10-30%. [2]

Build for a better environment

The construction industry is becoming more environmentally conscious, driven by initiatives like the Paris Climate Agreement. Efforts to reduce carbon emissions are impacting cement production, a major component of construction. The cement industry emits more than 4 billion tons of carbon each year and is actively testing carbon sequestration. [3] Sustainable alternatives like synthetic-based fly ash are changing the look and feel of construction materials but the industry is still determining the long-term effects of these changes.

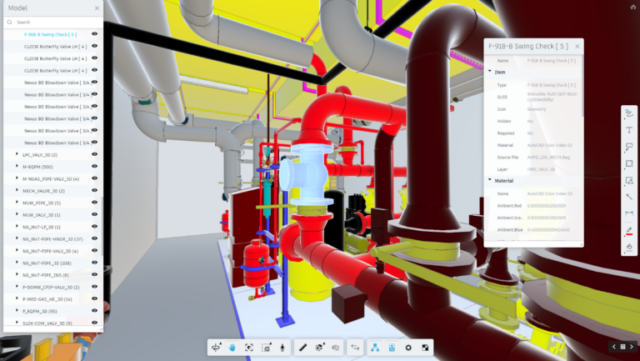

Manage the impact of technology

Advancements in robotics, autonomous equipment and other technologies like predictive analytics are revolutionizing construction. The adoption of technology is project-specific, focusing on customer needs and project requirements. Field applications, such as layout robots and devices that assist in printing or projecting wall and MEP locations, are freeing up craft workers for other tasks while ensuring accuracy and saving time and money. However, construction companies are still grappling with liability and safety issues inherent in certain technologies such as operating autonomous vehicles. [4]

Address worker shortages

The construction industry continues to face a skilled worker shortage and technology adoption is crucial in bridging this gap. Digital drawings, plans, and data are the industry standard, enabling fewer people to do more. A technology-enabled workforce allows for better project planning and management. Through its longstanding internships and apprenticeships, Riley is dedicated to training the next generation of skilled, tech-savvy construction professionals. Now is the time for our seasoned tradespeople to pass their knowledge on while being open to new ways of doing things. The single biggest stumbling block in moving our industry forward is the sentiment, “That’s how we have always done it.”

Mitigate safety issues with data

From camera technology that captures worksite footage to sensors that detect potential issues, construction companies deploy a variety of new safety technologies. These are used to identify and monitor potential issues, helping to reduce insurance risks. However, while AI tools can identify safety concerns, it is still important to empower field leaders and trade partners to work safely and communicate effectively. Riley prides itself on making safety a priority and building a culture that ensures employee well-being and minimizes risks and costs.

Adapt to material shortages

The construction industry has faced material shortages since the COVID-19 pandemic and a few supply chains, such as electrical components, continue to struggle three years later. The availability of steel has eased with lead times and pricing dropping dramatically. Construction companies and designers are adapting to these challenges by exploring alternative suppliers and diversifying their supply chains. Riley has learned that the key to expediting projects is early partnerships and the ability to change on the fly when material shortages arise. The consequences of not partnering early are significant cost increases and schedule delays.

Construction companies can thrive in an evolving landscape and deliver projects more efficiently and sustainably by staying abreast of these trends. To learn more about emerging trends in the construction industry, contact Riley President, Ben Kossow or Construction Technology Manager, Kevin Kendellen at trends@rileycon.com.