Right now, there are plenty of opportunities for growth in the commercial construction industry, as the number of new projects is up 29% since last year, according to Dodge Data & Analytics. Some key forces that will continue to have a massive impact on the industry are a volatile economy, a developing labor force, and emerging technologies.

Design and safety technologies will move projects forward

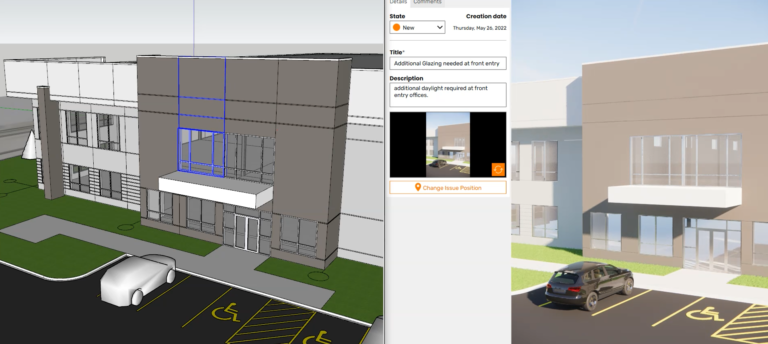

Technologies that impact safety, productivity, and cost are making major ripples in the world of commercial construction. As part of Riley’s core InSTEP® philosophy, our team will continue to invest in technologies like BIM (building information modeling) and reality capture to be productive, creative, and resourceful.

Many technologies help expedite projects without sacrificing the accuracy and efficiency of construction processes. Artificial intelligence, augmented reality, drones, robotics, and other technologies have the power to significantly decrease design timeframes, thereby keeping project scopes and budgets in check. These cost-effective efficiencies are evident in many of our projects. It begins in preconstruction when design parameters are established early within our building models and allow us to guide customers through their options using real-time data.

Technology also plays a lead role in construction safety. Our team is always reviewing and testing new products to eliminate hazards both on and off the jobsite. Examples of safety technologies include virtual reality for training, tools built for data collection and injury mitigation, and geofencing and wireless systems to provide secure access across large campuses and job sites. Other emerging technologies use advanced robotics to automate data collection and decrease hazardous conditions for our crews.

Riley continuously evaluates the latest technologies looking for new tools that provide more precise data to help efficiently plan and execute projects. It is also important to keep in mind that technology will never completely replace the human element of construction. Designers, architects, project managers, and other stakeholders bring unique problem-solving skills that are vital to a job well done.

Economic factors will continue to affect supplies and timelines

Today, the time to market — the length of time between a construction project’s conception and completion — is faster than ever before. Teams must be able to quickly pivot for success, especially as timelines continue to truncate and project requirements remain unpredictable until late in the construction process.

Materials are selected based on several factors, including cost, availability, quality, and overall sustainability. However, supply chain issues and material shortages can cause major delays that have greatly impacted deadlines and budgets. Due to some of these drastic economic shifts over the past few years, contractors have become more adept at finding replacements and new sources for everything from glass to ceiling joists to pipes – all without sacrificing quality, safety, or project schedules.

Inflation is yet another issue that impacts supplies. Riley has partnered with clients to help them navigate volatile pricing and avoid cost spikes of materials and land. Riley constantly monitors the market and regularly consults with clients regarding changes to ensure they get the best price possible. Looking ahead, inflation is expected to wane in 2023 according to ITR Economics. Overall, the outlook is positive for business in the months ahead.

Projects will become even more sustainable and feature more amenities

Sustainability and environmental responsibility have become increasingly important to communities and organizations. Corporate social responsibility is driving growth in sustainable construction projects – both large and small. Many customers, for instance, request that their properties be built with sustainable materials such as timber or include eco-friendly features such as solar panels or green roofs.

With modern technologies and techniques being developed to limit harmful emissions and reduce waste, the options are growing annually. Natural or recycled materials such as wood or clay may serve as an affordable, versatile, and eco-friendly substitution to traditional concrete or manufactured textiles. Many products that were once considered premium, including low VOC (Volatile Organic Compound) adhesives, are now mainstream. Net-zero steel is another material being used in construction to help offset the greenhouse gas (i.e., carbon) emissions in the earth’s atmosphere. McKinsey explains that shifting from high-emissions steel to net-zero steel in construction will help minimize its historically negative effects on the environment.

Perhaps not surprisingly, recruiting talent is a key influence as organizations consider their commercial building plans. Popular amenities like collaborative workspaces, cafeterias, and on-demand offices are also highly marketable.

The construction labor force will expand

With more students enrolling in trade schools, things are looking up for the construction industry. NPR reports that skilled trades programs have skyrocketed as young people opt to enter the workforce earlier and start making money rather than taking on mountains of college debt.

The stigma behind entering the trades in lieu of attending four-year colleges and universities has reduced considerably over the past several years. Vocational training is crucial, especially in today’s job landscape. Students and their families are waking up to the reality that trade school can be much more cost-effective and may lead to a clearer career path. From there, career opportunities are seemingly endless as the industry continues to evolve and utilize an increasingly diverse skill set in every aspect of our business. This allows individuals who may not have initially considered construction as their focal point a significant opportunity to contribute to one of the largest industries worldwide.

While there was a shortage of construction workers just a couple of years ago, as reported by the Associated General Contractors of America, the labor force is now on the rise. However, the number of retirees continues to create more demand for skilled trades workers. Innovative technologies and manufacturing-based processes are helping to augment workforce shortages. For example, layout and elevation verification efforts, which used to entail three-person crews, are now handled by one individual and a robotic total station. What was once a manual process that involved large-scale printing, transmittals, and updating drawings by hand is now digital thanks to BIM and other collaborative software solutions. This digital process ensures current project information is readily available to all stakeholders. Construction technology allows the commercial construction industry to adapt to new opportunities while also allowing the Riley team to investigate methods and tools that challenge the status quo in areas that have remained stagnant for years.

To learn more about emerging trends in the construction industry, contact Construction Technology Manager Kevin Kendellen at kevink@rileycon.com or Project Estimator Vincent Iacobucci at vincenti@rileycon.com.